TOPCon and Mono-Perc - A Comparative Analysis

- Hyde Source

- Jul 26, 2025

- 3 min read

The solar industry is in a constant state of innovation, with manufacturers continually pushing the boundaries of efficiency and performance. Two leading technologies dominating the market today are Mono PERC (Passivated Emitter and Rear Cell) and TOPCon (Tunnel Oxide Passivated Contact). While Mono PERC has been the workhorse for several years, TOPCon is rapidly emerging as the next generation, offering even higher efficiencies.

Comparative Analysis:

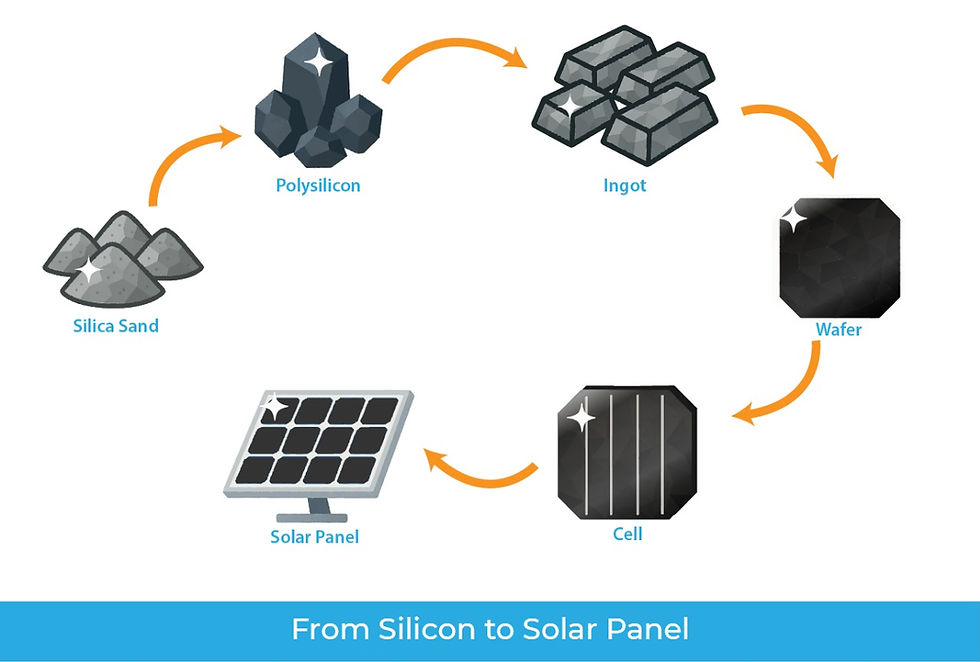

Manufacturing Process:

Mono PERC: Involves adding a few extra steps to standard monocrystalline cell production, primarily the deposition of the dielectric passivation layer and subsequent laser patterning. It's relatively well-established and less complex compared to TOPCon.

TOPCon: More complex than PERC. It involves additional process steps such as ultra-thin tunnel oxide deposition, followed by phosphorus-doped polysilicon deposition. While more intricate, many manufacturers can adapt existing PERC production lines with relatively manageable upgrades, reducing capital expenditure compared to building entirely new lines.

Efficiency:

Mono PERC: Typical mass production efficiencies range from 19-22%, with top-tier modules reaching up to 22.5%. While a significant leap from conventional cells, it's nearing its theoretical efficiency limit (around 24.5%).

TOPCon: Exhibits significantly higher efficiencies, typically ranging from 22-24% in mass production, with some manufacturers achieving even higher figures (up to 25-26% in commercial modules). Laboratory records have pushed beyond 28%. TOPCon is closer to the theoretical efficiency limit of silicon cells (~28.7%) than PERC.

Degradation:

Mono PERC: Generally has an initial degradation (LID - Light Induced Degradation) in the first year (around 1-2%) followed by an annual linear degradation rate of approximately 0.5% to 0.7% over 25-30 years. Modern manufacturing has largely mitigated severe LID.

TOPCon: Boasts a lower initial degradation (often less than 1%) and a significantly lower annual linear degradation rate, typically around 0.25% to 0.4% per year over 30 years. This means more power output over the panel's lifetime. N-type silicon's inherent resistance to LID and PID (Potential Induced Degradation) contributes to this.

Cost:

Mono PERC: Considered a mature and highly cost-effective technology. Its widespread adoption and scaled production have led to competitive pricing, offering a strong balance between performance and investment cost. Manufacturing costs are lower due to simpler processes.

TOPCon: Currently has a slightly higher manufacturing cost than PERC due to the more complex process steps and the use of N-type wafers (which are historically more expensive). This translates to a slightly higher initial module price. However, the cost gap is rapidly narrowing as TOPCon production scales up.

Temperature Performance (Temperature Coefficient):

Mono PERC: Has a good temperature coefficient, typically around −0.35%/∘C to −0.40%/∘C. This means for every degree Celsius above 25∘C, the power output decreases by this percentage. While good, it's generally not as strong as TOPCon.

TOPCon: Possesses a superior temperature coefficient, typically around −0.29%/∘C to −0.32%/∘C. This better performance in high-temperature environments means less power loss as temperatures rise, making TOPCon modules particularly well-suited for hot climates.

Bifaciality:

Mono PERC: Can be made bifacial by replacing the opaque back-sheet with a transparent one and optimising the rear contact pattern. Typical bifaciality factors range from 65-75%.

TOPCon: Inherently designed for excellent bifacial performance. N-type cells and the passivated contact structure result in higher bifaciality factors, often ranging from 80-85%. This allows them to capture significantly more reflected light from the rear side, boosting overall energy yield, especially in ground-mounted or elevated installations with high-albedo surfaces.

Mono PERC vs. TOPCon: Which is Better?

The choice between Mono PERC and TOPCon often boils down to a balance between cost, efficiency, and long-term performance priorities:

Choose Mono PERC if:

You are looking for a highly reliable and proven technology.

Budget is a primary concern, and you need a cost-effective solution with excellent efficiency.

Space is not extremely constrained.

Choose TOPCon if:

You want the highest possible efficiency and power output from a given footprint (e.g., limited roof space).

You prioritize long-term performance, lower degradation, and better yield in challenging conditions (high temperatures, low light).

You are willing to pay a slightly higher upfront cost for superior long-term returns and cutting-edge technology.

In summary, while Mono PERC has been a game-changer and remains a strong choice, TOPCon is the more advanced technology, offering higher efficiencies, lower degradation, and better performance across various environmental conditions.

As manufacturing scales, TOPCon is expected to become the dominant technology, offering increasingly competitive pricing, making it a highly attractive option for future solar installations.