Tips to Minimise Solar Power Generation Losses and Enhance Return on Investment

- Hyde Source

- Jul 27

- 4 min read

Solar power generation losses can significantly impact the overall energy yield and financial returns of a solar power plant. These losses can be categorized and mitigated through various strategies, from careful design and installation to ongoing maintenance and advanced technologies.

Here are tips to reduce all types of solar generation losses:

1. Soiling Losses (Dust, Dirt, Bird Droppings, Pollen):

Regular Cleaning: This is the most effective and straightforward method. The frequency depends on the location (e.g., dusty areas, industrial zones, coastal regions, or areas with less rainfall may require more frequent cleaning). Cleaning panels once every month is generally recommended.

Method: Use soft cloths or microfibre brushes with mild soap and de-ionized water. Avoid harsh chemicals or abrasive tools. Clean during early morning or evening when panels are cool to prevent thermal shock and water spots.

Automatic Cleaning Systems: For large-scale plants, automated robotic cleaning systems can be a cost-effective solution.

Optimal Tilt Angle: A steeper tilt angle can help with self-cleaning from rainfall, reducing dust accumulation.

2. Shading Losses:

Careful Site Assessment and Design:

Pre-installation Analysis: Thoroughly survey the site for potential shading from trees, buildings, chimneys, other solar rows (self-shading), and other obstructions throughout the year and different times of day (using tools like 3D modeling, LiDAR, and solar simulation software).

Optimal Layout and Spacing: Design the array layout to minimize inter-row shading and shading from fixed objects.

Module-Level Power Electronics (MLPEs):

Microinverters: Installed on each solar panel, microinverters convert DC to AC at the module level.This means if one panel is shaded, it only affects that panel's output, not the entire string.

Solar Micro-Inverters to optimize generation at the solar panel level DC Optimizers: These devices are installed at each module and optimize its power output before sending DC power to a central string inverter. They allow each panel to operate at its Maximum Power Point (MPP) independently, mitigating the impact of shading on the string.

String Inverters with DC Optimizers for Independent MPPT Tracking Bypass Diodes: Most modern panels come with built-in bypass diodes. These diodes create an alternate path for current to flow around shaded or malfunctioning cells within a module, preventing significant power loss and hotspot formation. However, they don't recover the lost power from the shaded cells themselves.

Bypass Diodes in a half-cut solar panel

Tree Pruning/Removal: If feasible, remove or prune trees that cast significant shadows.

3. Temperature Losses:

Proper Ventilation: Solar panels perform less efficiently as their temperature increases above 25°C.

Mounting Gaps: Ensure adequate space (several inches) between panels and the mounting surface (e.g., roof) to allow for air circulation and cooling.

Elevated Structures: Ground-mounted systems with elevated structures allow for better airflow underneath.

Panel Selection: Choose panels with a lower "temperature coefficient (Pmax)" on their datasheet. This value indicates how much the power output decreases for every degree Celsius rise above 25°C (typically around -0.3% to -0.5% per °C). Lower (closer to zero) is better.

Light-Colored Mounting Surfaces: Where applicable, light-colored roofs or ground surfaces can reflect heat, potentially keeping panel temperatures slightly lower.

4. Inverter Losses:

High-Efficiency Inverters: Select inverters with high peak efficiency and, more importantly, high "European efficiency" which represent performance under typical operating conditions.

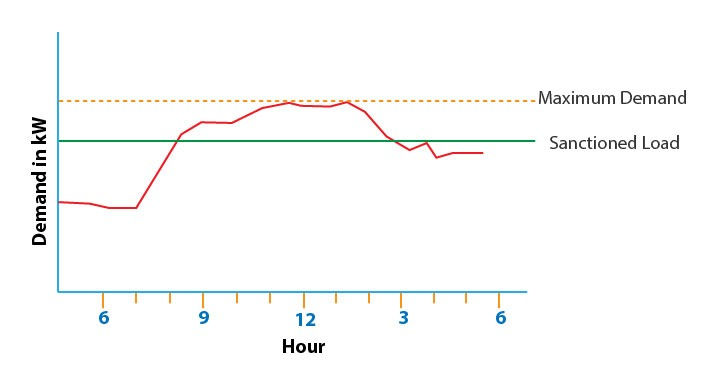

Optimal Sizing (DC:AC Ratio): Properly size the inverter capacity relative to the total DC power of the solar panels. An optimal DC:AC ratio (often between 1.2 to 1.3) can maximize energy harvest, balancing potential clipping losses at peak production with better performance in lower irradiance conditions.

MPPT (Maximum Power Point Tracking): Ensure inverters have efficient MPPT algorithms to continuously find the optimal operating point of the solar array under varying irradiance and temperature conditions. Multiple MPPTs are beneficial for arrays with different orientations or shading patterns.

Power and Voltage Relationship Proper Placement and Ventilation: Install inverters in cool, well-ventilated areas to prevent overheating, which can reduce efficiency and lifespan.

5. Wiring Losses (DC and AC):

Correct Wire Sizing (Gauge/Diameter): Use adequately sized (thicker) copper or aluminum cables for both DC and AC wiring. Larger wire diameters have lower resistance, minimizing voltage drop and power loss.

Minimize Cable Lengths: Design the system layout to keep cable runs as short as possible, especially for DC wiring from panels to the inverter.

High-Quality Connectors: Use high-quality, weather-resistant connectors (e.g., MC4 connectors for DC) to ensure good electrical contact and prevent resistance losses or degradation over time.

Professional Installation: Ensure wiring is done by qualified installers, following best practices to avoid loose connections, crimps, or improper insulation.

6. Mismatch Losses:

Binning of Modules: Use modules from the same production batch or "binned" for similar electrical characteristics to minimize mismatches in current and voltage.

MLPEs (Microinverters/Optimizers): As mentioned under shading, these devices are excellent at mitigating mismatch losses caused by slight differences in panel performance due to manufacturing tolerances, partial shading, or uneven degradation.

Proper Stringing: Design strings to have panels with similar performance characteristics and environmental exposure. Avoid mixing different panel types or orientations within the same string.

7. Degradation Losses:

High-Quality Panels: Invest in panels from reputable manufacturers with proven reliability and low degradation rates. Look for strong product and performance warranties.

ID (Light-Induced Degradation) Mitigation: Newer panel technologies and manufacturing processes (e.g., PERC, TOPCon, N-type cells, or specific annealing processes) are designed to reduce or eliminate the initial LID that can occur in the first few days/weeks of operation.

PID (Potential Induced Degradation) Resistance: Choose panels certified to be PID-resistant, especially in high-voltage systems and humid environments.

Regular Monitoring: Track the system's performance over time to detect any abnormal degradation rates early, allowing for timely intervention or warranty claims.

8. Inherent Optical Losses:

Anti-Reflective Coatings: Most modern solar panels come with anti-reflective coatings on their glass surface to maximize light absorption and minimize reflection losses.

Bifacial Panels: In suitable environments (e.g., ground-mounted with reflective surfaces like light-colored ground or snow), bifacial panels can capture sunlight from both the front and rear sides, increasing overall energy yield.

9. Monitoring and Analytics:

Real-time Monitoring System: Install a robust monitoring system that provides real-time data at the string or module level. This allows for immediate detection of underperforming panels, inverter faults, or other issues.

Performance Analysis: Regularly analyze performance data to identify trends, pinpoint specific loss types, and compare actual performance against expected performance (PR - Performance Ratio). This helps in proactive maintenance and optimization.

Predictive Maintenance: Utilize data analytics and, increasingly, AI/ML to predict potential failures or efficiency drops before they occur, enabling scheduled maintenance rather than reactive repairs.

By addressing these potential loss areas systematically, solar power plant owners and operators can significantly enhance the efficiency, reliability, and profitability of their solar assets.