The Battery Showdown: LiFePO4 vs. Lead-Acid for Modern Energy Storage

- Hyde Source

- Jul 27, 2025

- 4 min read

The landscape of energy storage is rapidly evolving, with Lithium Iron Phosphate (LiFePO4 or LFP) batteries increasingly challenging the long-standing dominance of Lead-Acid batteries.

While lead-acid batteries have served as a reliable and cost-effective solution for over a century, LFP technology offers significant advancements in performance, lifespan, and safety, making it a strong contender for various applications, particularly in renewable energy storage.

Let's delve into the design, technology, and a comprehensive comparative analysis of these two battery types.

Lead-Acid Batteries: The Traditional Workhorse

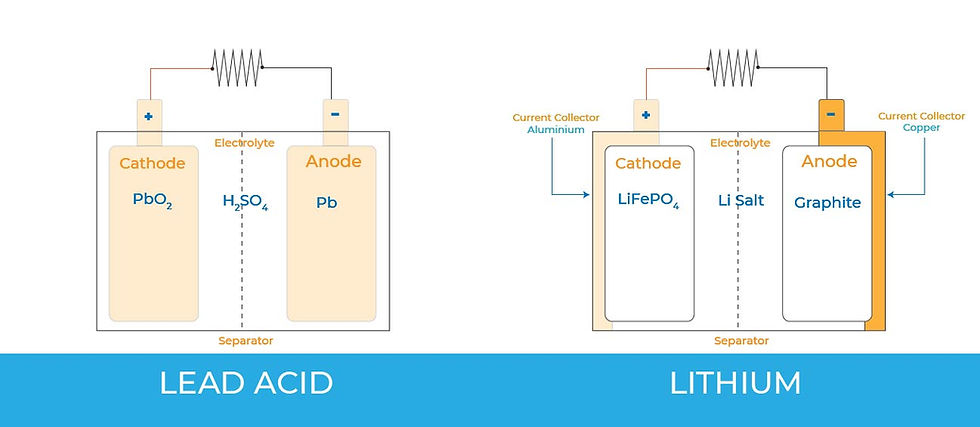

Lead-acid batteries consist of lead dioxide (positive plate) and sponge lead (negative plate) electrodes submerged in an electrolyte of sulfuric acid and water. During discharge, lead and lead dioxide react with sulfuric acid to form lead sulfate on the plates, releasing electrons.

During charging, this process is reversed.

There are primarily three types of lead-acid batteries used in energy storage:

Flooded Lead-Acid (FLA) / Wet Cell:

Design: The plates are fully immersed in a liquid electrolyte. They have removable caps to allow for electrolyte level checks and topping up with distilled water.

Technology: These are the oldest and most robust. They produce hydrogen gas during charging (venting required) and are susceptible to electrolyte stratification (acid settling at the bottom).

Applications: Commonly used in automotive starting, forklifts, and large-scale, low-cost stationary energy storage where regular maintenance is feasible.

Absorbed Glass Mat (AGM):

Design: A fiberglass mat is saturated with electrolyte and placed between the lead plates. The mat immobilizes the electrolyte.

Technology: Sealed, "maintenance-free" (no water topping). The glass mat helps in oxygen recombination, reducing gassing. They have lower internal resistance than FLAs, allowing for faster charging and higher discharge currents. They are also more resistant to vibration.

Applications: RVs, marine, UPS systems, power sports, and off-grid solar where a sealed battery is preferred.

Gel Cell:

Design: The electrolyte is immobilized in a silica gel, giving it a jelly-like consistency.

Technology: Also sealed and "maintenance-free." Gel cells are excellent for very deep discharge applications and perform well in higher temperatures. They have lower self-discharge rates than FLAs but are more sensitive to overcharging.

Applications: Wheelchairs, medical mobility scooters, solar streetlights, and applications requiring very deep, slow discharges.

Lithium Iron Phosphate (LiFePO4 / LFP) Batteries: The Modern Solution

LiFePO4 batteries are a type of lithium-ion battery that uses lithium iron phosphate as the cathode material, a graphite carbon electrode with a metallic backing as the anode, and a lithium salt electrolyte. They are known for their exceptional thermal stability, long cycle life, and inherent safety compared to other lithium-ion chemistries (like NMC or NCA).

Key Components and Function:

Cathode: LiFePO4 (Lithium Iron Phosphate) - Provides a stable crystal structure.

Anode: Typically graphite or a blend of graphite and silicon.

Electrolyte: A non-aqueous solution containing lithium salts, allowing lithium ions to move between the electrodes.

Separator: A porous membrane that prevents direct contact between cathode and anode while allowing ion flow.

Battery Management System (BMS): This is a crucial component for LFP batteries. It actively monitors and manages the battery pack's critical parameters, including:

Cell Balancing: Ensures all cells in the pack are charged and discharged uniformly to prevent overcharging or deep discharging of individual cells.

Over-voltage/Under-voltage Protection: Prevents cells from exceeding safe voltage limits during charging or discharging.

Over-current Protection: Shuts off power if discharge current is too high.

Over-temperature Protection: Monitors temperature to prevent overheating.

Short-circuit Protection: Prevents damage from accidental short circuits.

State of Charge (SoC) / State of Health (SoH) Estimation: Provides accurate readings of battery capacity.

How it Works:

During discharge, lithium ions move from the anode through the electrolyte and separator to the cathode. Electrons flow through an external circuit, generating electricity. During charging, the process reverses. The stable crystal structure of LiFePO4 contributes to its safety and longevity.

Pros of LiFePO4 Batteries:

High Energy Density: Much lighter and more compact for the same energy capacity (typically 3-4 times lighter than lead-acid).

Exceptional Cycle Life: 2,000 to 10,000+ cycles, depending on DoD and quality. This is significantly longer than lead-acid.

High Depth of Discharge (DoD): Can be safely discharged to 80-100% of their capacity regularly without significantly impacting lifespan. This means more usable energy.

High Efficiency: Round-trip efficiency typically 90-99%. Minimal energy loss during charge/discharge.

Fast Charging/Discharging: Can accept and deliver high currents, leading to faster charging times and better performance in high-power applications.

Consistent Voltage: Maintain a very stable voltage throughout most of their discharge cycle.

Excellent Temperature Performance: Wider operating temperature range and better performance in both hot and cold conditions compared to lead-acid. Highly thermally stable, reducing risk of thermal runaway.

Low Maintenance: Virtually maintenance-free.

Enhanced Safety: Inherently stable chemistry, less prone to overheating, fire, or explosion. No corrosive acid or explosive gas emissions.

Environmentally Friendlier: Do not contain toxic heavy metals like lead or cadmium, and their longer lifespan means less waste over time.

Cons of LiFePO4 Batteries:

Higher Initial Cost: The main drawback is a significantly higher upfront purchase price compared to lead-acid.

BMS Requirement: The absolute necessity of a Battery Management System adds to the complexity and cost, but it's crucial for safety and longevity.

Charging Compatibility: Requires specific chargers or inverter settings compatible with lithium battery charging profiles.

Comparative Analysis: LiFePO4 vs. Lead-Acid Batteries

Conclusion

While Lead-Acid batteries remain a viable option for low-budget, less demanding applications where initial cost is paramount and space/weight are not critical, their inherent limitations in terms of usable capacity, cycle life, efficiency, and maintenance make them less ideal for modern, high-performance energy storage needs, particularly in solar PV systems where long-term reliability and energy harvest are key.

Lithium Iron Phosphate (LiFePO4) batteries, despite their higher initial cost, offer a compelling long-term value proposition. Their superior cycle life, high usable capacity, excellent efficiency, safety, and minimal maintenance requirements translate into a significantly lower total cost of ownership and a more reliable, high-performing energy storage solution. For solar on-grid or off-grid systems, electric vehicles, and other demanding applications, LFP batteries are increasingly becoming the technology of choice, representing a crucial step forward in sustainable energy storage.