Solar PV Panel Components

- Hyde Source

- May 9, 2020

- 2 min read

Updated: Jul 30, 2025

Aluminium Frame

The Aluminium frame provides the structural stability for the overall combination of glass, EVA encapsulant, the cell, and the back sheet. It plays a significant role by both protecting the edge of the laminate section housing the cells and providing a structure to mount the solar panel in position. The aluminium sections are designed to be extremely lightweight and able to withstand extreme stress and loading from high wind and external forces.

Glass

The front glass protects the PV cells from the weather and impact from hail or airborne debris. The glass is high strength tempered glass, which is 3.0 to 4.0mm thick and is designed to resist mechanical loads and extreme temperature changes. In the event of severe impact on the panel, the tempered glass shatters into tiny fragments rather than sharp jagged sections as in standard glasses.

High transmissive glass, which has very low iron content and an anti-reflective coating on the rear side, is used to improve efficiency and performance.

EVA Film

EVA stands for 'ethylene vinyl acetate,' a specially designed polymer highly transparent (plastic) layer used to encapsulate the cells and firmly hold them in position during the panel manufacture. The EVA material is extremely durable and tolerant of extreme temperature and humidity; it plays an integral part in a long-term performance by preventing moisture and dirt ingress. The lamination on either side of the solar PV cells provides some shock absorption. It helps protect the cells and the interconnecting wires from vibrations and sudden impact from hailstones and other objects. During manufacture, the solar cells are first encapsulated with the EVA before being assembled within the glass and back sheet.

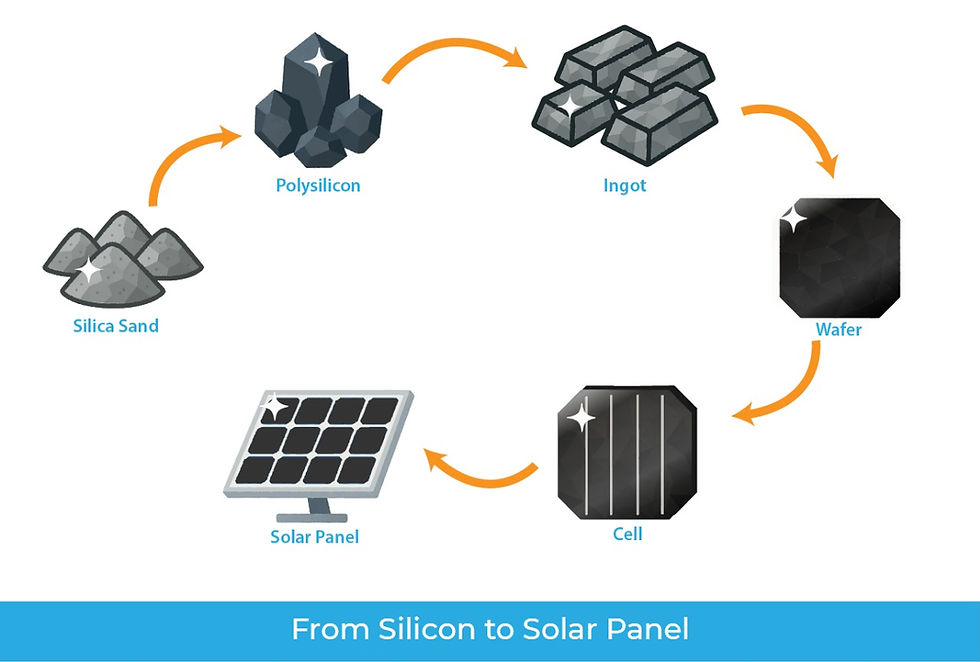

Solar PV Cells

Solar photovoltaic cells convert sunlight directly into DC electrical energy. The solar panel's performance is determined by the cell type and characteristics of the silicon used. There are different cell sizes and configurations available that offer different levels of efficiency and performance, including half-cut or split cells and multi-busbar (MBB) cells.

Backsheet

The back sheet is the rearmost layer of standard solar panels, which acts as a moisture barrier and final external skin to provide mechanical protection and electrical insulation. The back sheet material is made of various polymers or plastics, which offer different levels of protection, thermal stability, and long term UV resistance. The back sheet layer is typically white in color but is also available as clear or black, depending on the manufacturer and module.

Ready to go solar? We're here to help! Reach out to our experts today for a personalized discussion about your specific requirements. We'll craft the ideal solar system that perfectly fits your needs and budget.