Powering Your Plant: Essential Cable Considerations for Solar Plants

- Hyde Source

- Jul 29, 2025

- 3 min read

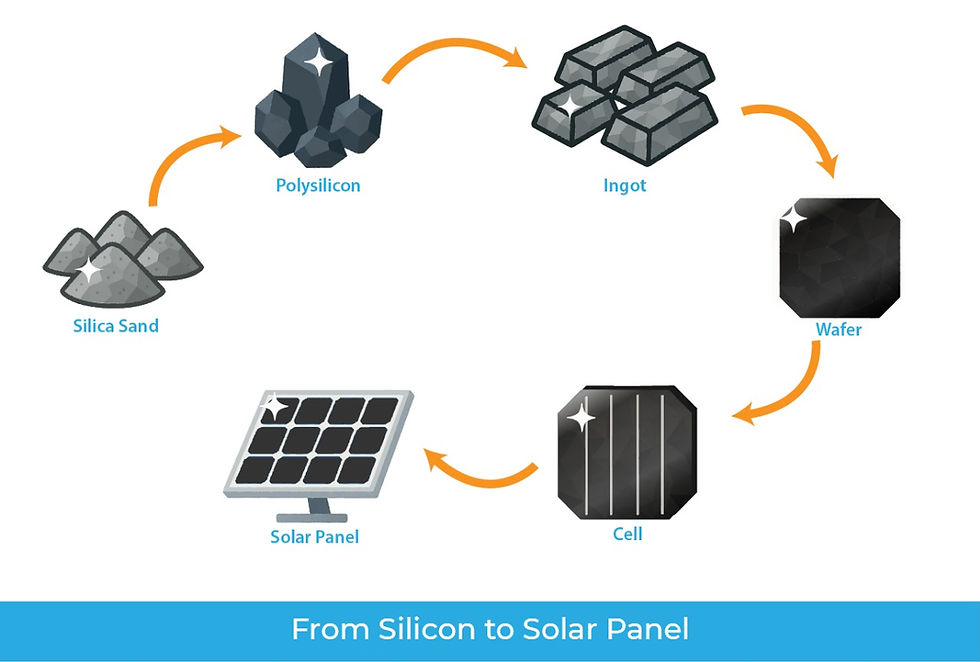

In the grand scheme of a solar power plant, the panels capture the sun's energy, and the inverters convert it into usable electricity. But what connects these vital components, ensuring the power flows efficiently and safely? The answer lies in the often-overlooked, yet critically important, cables and wiring.

Proper cable sizing is not just a recommendation; it's a fundamental requirement for the optimal performance, safety, and longevity of any solar power system, from a small rooftop installation to a large utility-scale plant.

Undersized cables can lead to significant energy losses, overheating, equipment damage, and even fire hazards. Oversized cables, while safe, can lead to unnecessary costs.

This blog post will delve into the key considerations involved in cable wiring for solar power plants, helping you understand the science behind efficient and safe power transmission.

Why Cable Sizing Matters: The Impact of Voltage Drop

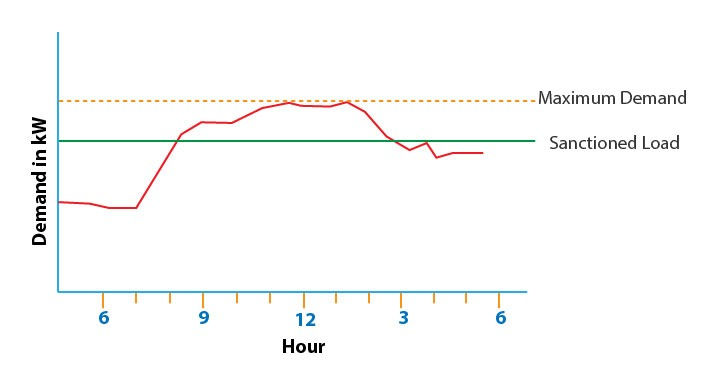

The primary reason for meticulous cable sizing in solar systems is to minimize voltage drop. Voltage drop refers to the reduction in electrical potential (voltage) that occurs as current flows through a conductor (cable) due to its inherent resistance. The longer the cable and the smaller its cross-sectional area, the higher the resistance and, consequently, the greater the voltage drop.

Consequences of Excessive Voltage Drop:

Reduced Efficiency: Lower voltage reaching the inverter or load means less power is converted or utilized, directly impacting the solar plant's overall energy yield and financial returns.

Underperforming Equipment: Solar Inverters, charge controllers, and other components are designed to operate within specific voltage ranges. Excessive voltage drop can cause them to operate inefficiently or even fail prematurely.

Overheating and Safety Risks: Cables that are too small for the current they carry will heat up excessively, potentially damaging insulation, increasing fire risk, and accelerating cable degradation.

Voided Warranties: Many equipment manufacturers specify limits for voltage drop, and exceeding these limits can void warranties.

Recommended Voltage Drop Limits:

DC Side (Panels to Inverter/Combiner Box): Typically, voltage drop should be kept below 1-3% of the system voltage.

AC Side (Inverter to Grid/Load): Usually, voltage drop should be kept below 1-2% of the system voltage.

Key Factors Influencing Cable Sizing

Several critical factors must be considered when calculating the appropriate cable size:

Current (Amperage): This is the most crucial factor. The cable must be able to safely carry the maximum expected current without overheating. Solar panels produce current based on their specifications (Imp - Current at Maximum Power, Isc - Short Circuit Current). Inverter output current is also a key consideration for the AC side.

Voltage: The system voltage (DC voltage of strings, AC output voltage of inverter) dictates the insulation requirements of the cable and influences voltage drop calculations. Higher voltages generally allow for smaller cables for the same power, as current will be lower.

Cable Length: The distance between components (panels to combiner box, combiner box to inverter, inverter to main electrical panel) directly impacts voltage drop. Longer runs require thicker cables to maintain acceptable voltage drop limits.

Conductor Material:

Copper: Excellent conductivity, lower resistance, smaller diameter for a given current, more durable, but generally more expensive.

Aluminum: Lighter and cheaper than copper, but has lower conductivity, requiring a larger cross-sectional area for the same current capacity.

Environmental Factors & Temperature:

Ambient Temperature: Higher temperatures reduce a cable's current-carrying capacity (ampacity). Cables must be "derated" based on the maximum expected ambient temperature.

Installation Method: Cables installed in conduits, buried underground, or bundled together will dissipate heat less effectively than those in open air, requiring further derating.

UV Resistance: Outdoor solar cables must be UV-resistant to prevent degradation from sunlight.

Conclusion

Cable wiring calculations are a cornerstone of efficient and safe solar power plant design. By meticulously considering factors like current, voltage, length, material, and environmental conditions, and by adhering to stringent safety standards, we ensure that every watt generated by your solar panels reaches its destination with minimal loss.

Understanding the importance of voltage drop and the factors influencing cable sizing empowers you as a solar system owner to appreciate the hidden complexities that contribute to a high-performing and reliable solar investment.

Don't underestimate the wires – they are the arteries of your solar power plant, and their proper sizing is critical for a healthy, long-lasting system.