AC Junction Box: Design in Solar Power Plants

- Hyde Source

- Aug 1, 2025

- 3 min read

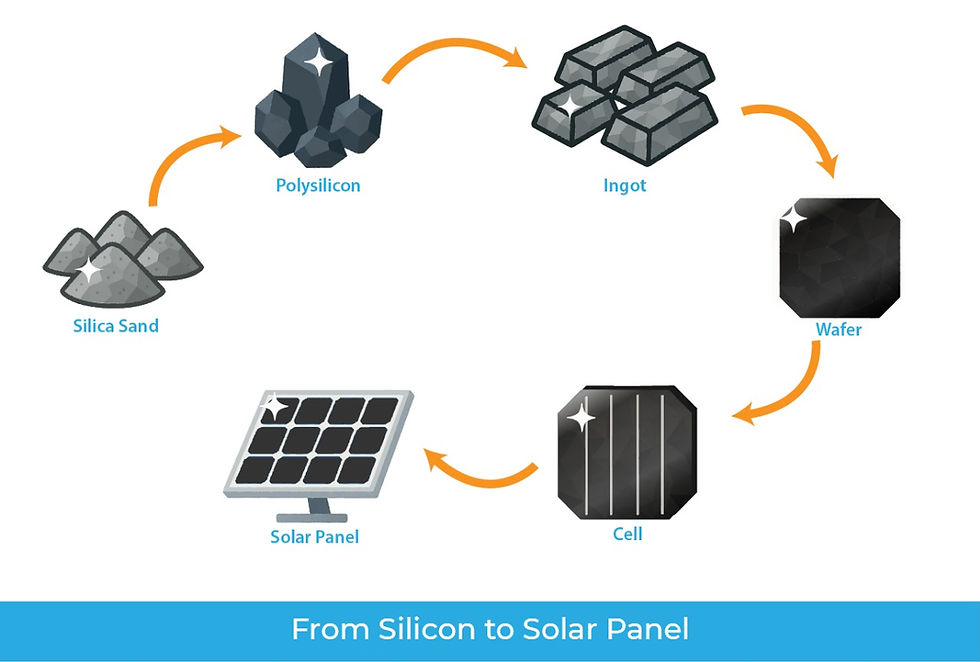

In a solar power plant, the journey of electricity begins with direct current (DC) from the panels, which is then converted into alternating current (AC) by inverters. While DC junction boxes (combiner boxes) aggregate power on the DC side, there's another crucial component that manages the AC output: the AC Junction Box, often referred to as an AC Combiner Box or AC Distribution Box (ACDB).

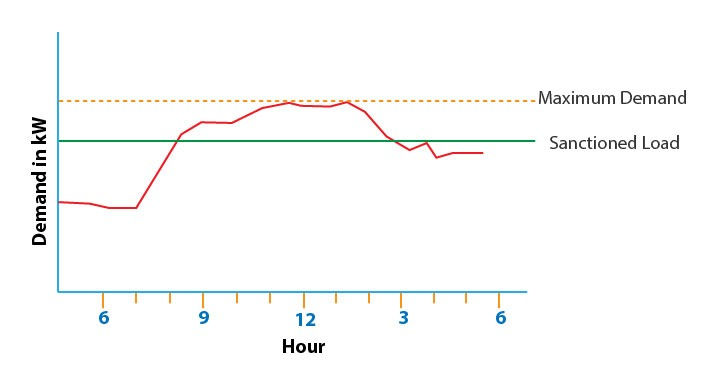

The AC junction box plays a vital role in ensuring the safe, efficient, and controlled distribution of AC power from multiple inverters to the main electrical panel or directly to the grid. Its proper design and sizing are paramount for the overall reliability and performance of the solar power plant.

What is an AC Junction Box (ACDB)?

An AC Junction Box is an electrical enclosure positioned on the AC side of a solar power system, typically after the inverters. Its primary function is to consolidate the alternating current (AC) output from multiple solar inverters into a single, larger AC feeder cable that connects to the main electrical distribution system or the utility grid.

The Critical Role of the AC Junction Box

The AC junction box serves several essential functions:

Inverter Aggregation: For larger solar power plants with multiple inverters, the ACDB combines their individual AC outputs in parallel, allowing for a more streamlined connection to the grid or load.

Overcurrent Protection: It houses circuit breakers or fuses for each incoming inverter circuit, providing crucial protection against overcurrents and short circuits on the AC side.

Surge Protection: Many ACDBs include Surge Protection Devices (SPDs) to safeguard inverters and other downstream equipment from voltage spikes caused by lightning strikes or grid disturbances.

Disconnect Means: ACDBs often incorporate main AC disconnect switches, enabling safe isolation of the entire solar AC system from the grid for maintenance, troubleshooting, or emergency shutdowns.

Key Design Considerations for AC Junction Boxes

Designing an AC junction box requires careful attention to safety, environmental factors, and operational efficiency:

Safety Standards: Adherence to local electrical codes is non-negotiable. This includes proper grounding, overcurrent protection, and the ability to safely isolate circuits.

Environmental Protection (IP Rating): ACDBs are typically installed outdoors, so they must have an adequate Ingress Protection (IP) rating (e.g., IP65, IP66, IP67) to protect internal components from dust, moisture, rain, and other environmental elements.

Temperature Management: The enclosure must be designed to effectively dissipate heat generated by internal components, especially circuit breakers and busbars, to prevent overheating and ensure longevity. Adequate ventilation or appropriate sizing is crucial.

UV Resistance: Materials used for the enclosure and internal components must be UV-resistant to withstand prolonged exposure to sunlight without degrading.

Accessibility & Maintenance: The internal layout should be organized and allow for easy access to circuit breakers, terminals, and other components for inspection, maintenance, and troubleshooting.

Material Selection: Enclosures are commonly made from durable materials like painted steel (CRCA), fiberglass-reinforced plastic (FRP), or polycarbonate, chosen for their weather resistance, strength, and electrical insulation properties.

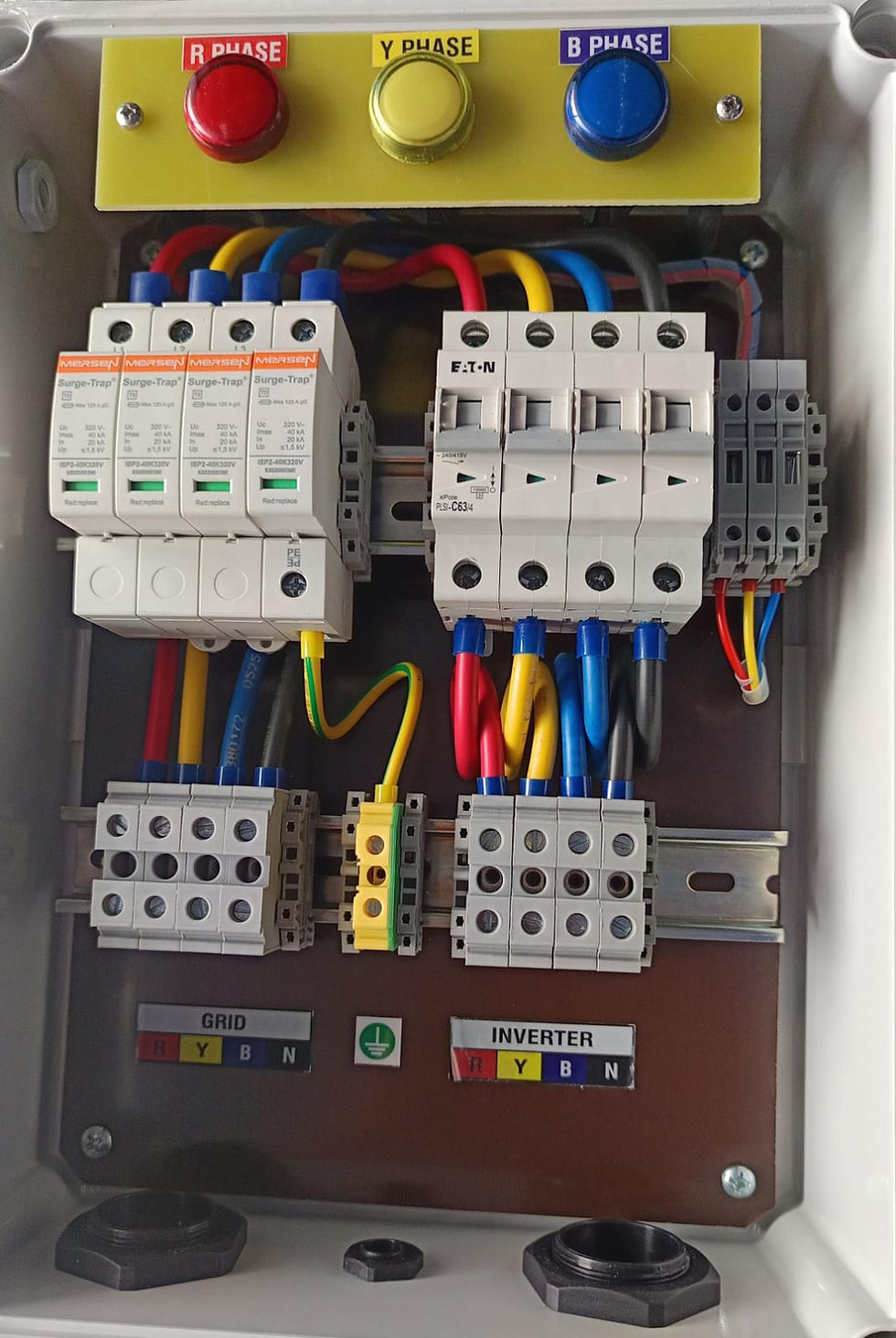

Components of a Typical AC Junction Box (ACDB)

A standard AC junction box typically includes:

Input Circuit Breakers (MCBs/MCCBs): Miniature Circuit Breakers (MCBs) for smaller systems or Molded Case Circuit Breakers (MCCBs) for higher loads, protecting each inverter's output.

Busbars: Copper or aluminium conductive bars that combine the AC current from all protected inverter circuits.

Surge Protection Devices (SPDs): To protect against voltage surges.

Output Terminals: For connecting the main feeder cable to the grid or load.

Cable Entry Glands & Terminal Blocks: For secure, weatherproof cable entry and organized internal wiring.

Enclosure: The robust, weather-resistant housing that protects all internal components.

Installation and Best Practices

Location: Install the ACDB as close as practically possible to the inverters to minimize AC cable runs and associated voltage drop.

Mounting: Securely mount the box on a stable surface, ensuring proper ventilation and protection from direct sunlight if possible.

Wiring: Use appropriate AC-rated cables, ensure proper crimping of terminals, and maintain neat, organized wiring to prevent hot spots and facilitate troubleshooting.

Grounding: The ACDB enclosure and all metallic components must be properly grounded according to electrical codes to ensure safety.

Labeling: Clearly label all circuits, breakers, and disconnects for easy identification and safe operation.

Regular Inspection: Periodic checks for loose connections, signs of wear, corrosion, or tripped breakers are essential for long-term reliability.

Conclusion

The AC junction box, or ACDB, is a vital link in the solar power plant's electrical chain, ensuring the safe and efficient aggregation and distribution of AC power from multiple inverters. Its meticulous design and accurate sizing, based on factors like inverter output, system voltage, and adherence to electrical codes, are critical for maximizing energy yield, protecting valuable equipment, and ensuring the long-term reliability of your solar investment.

Ready to go solar? We're here to help! Reach out to our experts today for a personalized discussion about your specific requirements. We'll craft the ideal solar system that perfectly fits your needs and budget.